Tips for Air Compressors to Beat the Summer Heat

The relentless heat of summer poses not only a continuous "grill" challenge for laborers but also significant difficulties for the operation of air compression equipment. Prolonged exposure to high temperatures can not only reduce the operating efficiency of air compressors but also lead to surge, malfunctions, and even structural damage in severe cases.

To mitigate the operational risks of air compressors under high-temperature conditions, maintain stable and efficient performance, and ensure that users' production plans proceed as scheduled, users must adopt a series of necessary measures during hot weather to ensure that their air compression equipment can comfortably "beat the heat" and operate continuously.

- Regular Inspection and Replacement of Air Filters

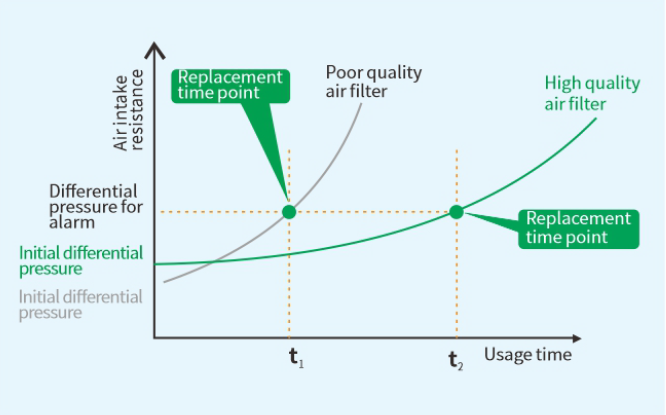

As a crucial component ensuring the normal operation of air compressors, air filters effectively prevent impurities and oil contaminants in the air from entering the compressor's interior. If the filter mesh in the air filter becomes clogged or its filtration effect decreases, it can hinder the intake and exhaust processes of the compressor, making it difficult to expel internal impurities and accumulated heat. During summer's intense heat, these issues can lead to sudden shutdowns, affecting production schedules and increasing maintenance costs.

In high-temperature environments, timely replacement of old air filters is particularly important. This not only ensures that the compressor operates at its optimal state but also effectively prevents various faults caused by high temperatures, providing a solid guarantee for continuous and stable production operations.

Regularly replacing IHI Sullair's high-quality air filters can significantly reduce the intake resistance of air compressors.

- Cleaning the Cooler

The cooler's primary responsibility is to cool compressed air to prevent the compressor from overheating. In summer's high-temperature environment, the cooler's surface is prone to accumulating dust and impurities, reducing its heat dissipation efficiency, causing the compressor's operating temperature to rise abnormally, and thereby affecting the stability and safety of the entire system.

Given this, users should thoroughly clean the cooler's surface regularly to ensure its heat dissipation performance remains optimal. It is generally recommended to perform cleaning maintenance at least once a month or use compressed air to blow off dust and dirt adhering to the cooler's surface. These measures can significantly improve the cooler's heat dissipation effect, effectively extend the compressor's service life, and ensure efficient and stable operation.

- Inspecting Lubricating Oil

Lubricating oil plays a vital role in air compressors, providing lubrication, sealing, cooling, and cleaning functions. Under high-temperature conditions, a lack of lubrication within the compressor's internal structure can easily lead to expansion, wear, and even deformation. Regularly checking the oil level of the lubricating oil to ensure it remains within the normal range and selecting high-quality lubricants such as IHI Sullair's dedicated lubricating oil are crucial to prevent oil deterioration and impurities.

Lubricating oil is essential for the normal operation of air compressors. It not only provides necessary lubrication but also effectively realizes sealing, cooling, and cleaning functions. In high-temperature environments, if the compressor's internal structure lacks proper lubrication, it can easily lead to component expansion, accelerated wear, and even deformation, significantly affecting the equipment's reliability and service life.

Therefore, regularly checking the oil level of the lubricating oil is an indispensable maintenance step during summer. Ensuring that the oil level remains within the specified normal range can effectively prevent the occurrence of the above problems. Additionally, users should choose genuine IHI Sullair dedicated lubricating oil, which boasts exceptional quality and performance, significantly reducing the risk of faults caused by high temperatures and maintaining the compressor's optimal operating state.

- Maintaining the Motor System

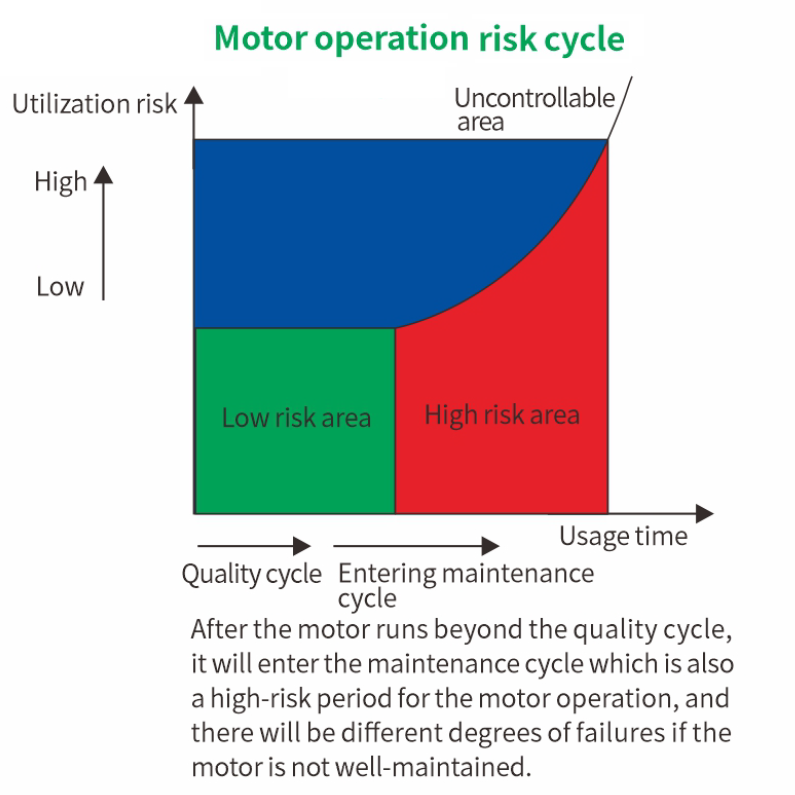

As the core power source of air compressors, the stability of the motor system directly affects the compressor's overall operating efficiency. In high-temperature environments, ensuring the reliability and safety of the motor system is particularly important.

First, regularly inspect the electrical system's wiring, cables, and protection and cooling devices to ensure no damage, looseness, or abnormal heating occurs. Any damage or aging can pose safety hazards. Second, conduct a comprehensive inspection of the electrical components within the control box to ensure all key components are in good working condition. If any components are found to be faulty or their performance has declined, take prompt repair measures or replace them to avoid equipment failure risks.

Regular maintenance of the main motor can significantly reduce the operational risks of air compressors under harsh conditions.

- Preventing Overheating and Rusting from Moisture

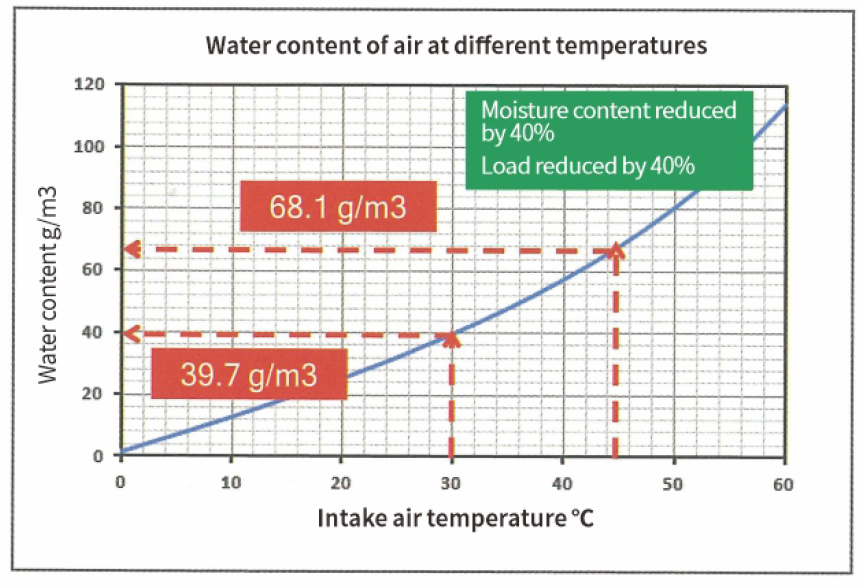

Preventing overheating and rusting is crucial to ensuring the safe and stable operation of air compressors in summer's high-temperature environment.

As temperatures rise, the risk of air compressors overheating increases, potentially leading to automatic shutdowns and significantly affecting production efficiency. Therefore, regularly inspecting the compressor's cooling system and promptly monitoring equipment temperatures become essential. To ensure the cooling system operates normally, consider adding additional cooling equipment or adopting other auxiliary cooling measures when necessary.

Moreover, southern China's summer not only brings high temperatures but also high humidity, increasing the likelihood of rusting in air compressors. Therefore, during the compressor's routine maintenance, special attention should be paid to keeping the equipment's surface dry and regularly applying anti-rust oil to prevent rusting. Pay particular attention to the rust prevention of key components and connections.

Summer's intense heat and high temperatures are peak periods for air compressor failures.

As a professional provider of comprehensive compressed air solutions, IHI Sullair boasts extensive manufacturing service technology and experience, assisting customers in ensuring that our air compressors operate safely, efficiently, and stably regardless of location or time.

We are committed to providing users with comprehensive services and support, including but not limited to professional maintenance plans, performance optimization solutions, and emergency troubleshooting services. IHI Sullair offers customized air compressor energy efficiency guarantees and enhancement services, and through long-term maintenance agreements with users, we provide a solid technical backing to ensure that your air compressor system remains in optimal condition when facing the challenges of summer heat.